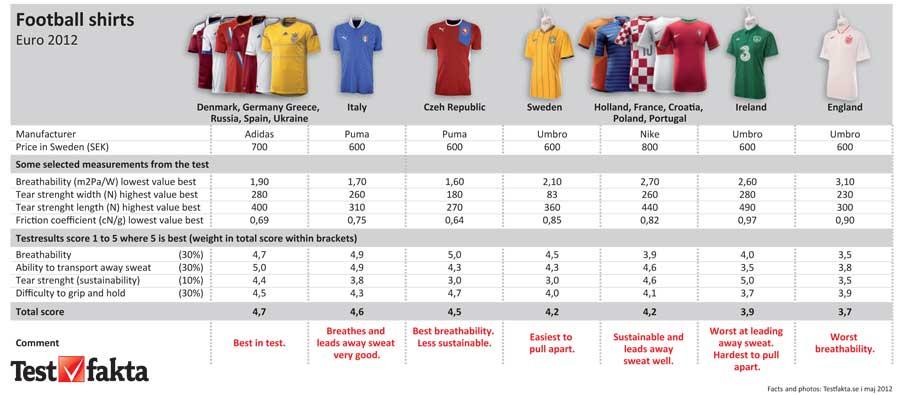

Testfakta have for this summer's European football championship (UEFA EURO 2012) compared the performance of all participating national teams shirts. The test is performed by the independent textile lab Swerea IVF in Mölndal, Sweden. The laboratory has investigated how well the shirts breathe, leading away the sweat and how easy they are to pull apart. In addition, the laboratory compared how easy or difficult it is to hold onto the shirts.

Shirts

Four major shirt companies are represented at this summer's European Championships. Adidas and Nike have the same material in all of their team shirts. Therefore, the laboratory only tested one shirt each from these two companies. Umbro and Puma, however, make different shirts for their teams and therefor all shirts from these two companies were tested.

These shirts have been tested:

- Adidas (Denmark, Greece, Russia, Spain, Germany, Ukraine)

- Nike (France, Netherlands, Poland, Croatia, Portugal)

- Puma Italy

- Puma Czech Republic

- Umbro England

- Umbro Ireland

- Umbro Sweden

Three shirts from each company/country were used in the test.

Breathability

The laboratory measured the shirts breathability according to the standard EN 31092:1994 / ISO 11 092:1993. The material's resistance to let through moisture vapor were measured – the lower the resistance is the better the material breathes

Three pieces from each shirt were tested - one from the front and two from the back. The mean value of these three have formed the basis for the grade in this subsection.

Ability to transport away sweat

Sweat moves through the fabric in three directions: on the inner side of the garment, through the fabric to the outer side and on the outside of the materials to eventually evaporate from the fabric. If the material has the ability to spread the moisture in all three directions and over a large area, the garment is perceived as less wet and it dries quickly.

The laboratory uses a Moisture Management test, according to the standard AATCC 195:2009. The equipment registrates how moisture spreads through the material and the speed at which this occurs.

Five pieces from each shirt were tested - four from the body and one from the lower sleeve. A mean value was calculated and the shirts total moisture transport was graded on a five-point scale according to the standard.

Tear strenght (sustainability)

The laboratory examined the amount of force required to tear the shirts apart (both length and width). Five pieces for each direction was used and the results are a mean value of these five.

Retaining test

The laboratory examined how easy it is for an opponent to get hold of the shirt by by measuring the material's coefficient of friction, according to European standard EN 14 882:2005. The higher the friction is, the easier to grip the shirt. The laboratory measured the friction on both the front and back and on the sleeves.

The laboratory also measured the force required to hold on to the shirt. The material was strapped in a canvas-covered clip, corresponding to a restraining hand. Then the laboratory measured the force in Newton which is required to pull the material from the clip at a speed of one meter per minute. The lower this value is, the better.